Pipe Inspection System

500000.00 INR/Unit

Product Details:

- Usage Pipe Inspection Camera

- Height 35 Centimeter (cm)

- Length 59 Centimeter (cm)

- Width 69 Centimeter (cm)

- Weight 40 Kilograms (kg)

- Product Type Pipe Inspection Camera

- Power Electronic

- Click to View more

X

Pipe Inspection System Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Pipe Inspection System Product Specifications

- 59 Centimeter (cm)

- 69 Centimeter (cm)

- 40 Kilograms (kg)

- Pipe Inspection Camera

- Electronic

- Manual

- 35 Centimeter (cm)

- 100 %

- Pipe Inspection Camera

- Manual

Pipe Inspection System Trade Information

- 7-10 Days

- Contact us for information regarding our sample policy

- All India

Product Description

A pipe inspection system is a technology-driven solution designed to assess the condition of pipelines, typically used in industries such as oil and gas, water management, and utilities. These systems are crucial for ensuring the integrity, safety, and efficiency of pipeline networks.

Here's an overview of how they work and their key components:

1. Pipeline Inspection Tools (PIGs): PIGs are devices inserted into the pipeline and propelled by the flow of the product being transported or by a separate driving mechanism. They are equipped with sensors and cameras to gather data about the condition of the pipeline interior. There are different types of PIGs, including smart PIGs, which are equipped with advanced sensors for detecting defects, corrosion, cracks, and other anomalies.

2. Sensors and Cameras: Modern pipe inspection systems are equipped with various sensors such as ultrasonic, electromagnetic, and laser sensors to detect defects, measure wall thickness, and assess the overall condition of the pipeline. High-resolution cameras are also used to capture images and videos of the pipe's interior, providing visual inspection capabilities.

3. Data Collection and Analysis Software: Data collected by the sensors and cameras are processed and analyzed using sophisticated software algorithms. This software can detect abnormalities, measure dimensions, identify corrosion, and generate detailed reports on the condition of the pipeline.

4. Communication and Control Systems: Pipe inspection systems often include communication modules that allow real-time monitoring and control of the inspection process. This enables operators to remotely track the progress of the inspection, receive alerts for critical issues, and make informed decisions based on the inspection data.

5. Navigation and Tracking Systems: To ensure accurate inspection coverage and precise location tracking within the pipeline network, pipe inspection systems may incorporate GPS, gyroscopes, and other navigation technologies.

6. Power Supply: Depending on the design and application, pipe inspection systems may be powered by the flow of the product within the pipeline, batteries, or external power sources.

7. Robotic or Autonomous Operation: Some advanced pipe inspection systems utilize robotic or autonomous vehicles to navigate through pipelines, especially in challenging environments or inaccessible areas.

Benefits of Pipe Inspection Systems:

1. Early Detection of Defects: Pipe inspection systems help identify defects and potential problems in pipelines before they escalate into more significant issues, reducing the risk of pipeline failures and costly repairs.

2. Improved Safety: By enabling remote inspection and monitoring, pipe inspection systems minimize the need for manual inspection activities in hazardous environments, enhancing safety for operators and technicians.

3. Optimized Maintenance: Inspection data provided by these systems allows operators to prioritize maintenance activities, schedule repairs proactively, and extend the lifespan of pipelines, resulting in cost savings and operational efficiency.

4. Regulatory Compliance: Many industries are subject to stringent regulations regarding pipeline integrity and safety. Pipe inspection systems help operators comply with these regulations by providing accurate and comprehensive inspection data for regulatory reporting purposes.

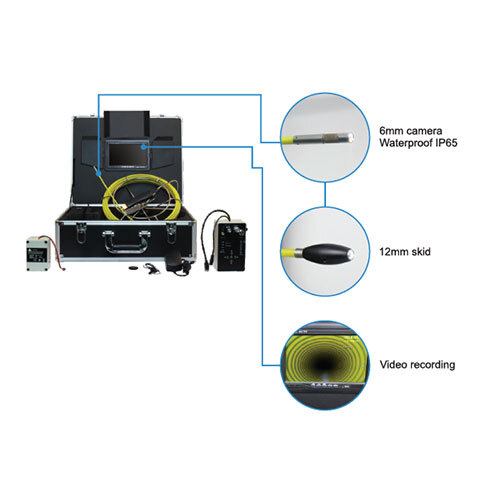

Pipe Inspection System Specifications:

1. Screen Size: 10 inch LCD IPS Screen, 1280*720 resolution

2. Camera Size: 1/3 CMOS,1.3MP pixel AHD 50mm camera head

3. Cable Reel: 7mm Fibreglass rod push cable reel

4. Power Supply: 12V 8800mA Rechargeable

FAQs of Pipe Inspection System:

Q: What is the length of the Pipe Inspection System?

A: The length of the system is 59 centimeters.

Q: What is the power source of the Pipe Inspection System?

A: The system is powered by electronic means.

Q: What is the operating mode of the Pipe Inspection System?

A: The operating mode is manual.

Q: What is the weight of the Pipe Inspection System?

A: The system weighs 40 kilograms.

Q: What is the accuracy of the Pipe Inspection System?

A: The accuracy is 100%.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free