Pipe Inspection Camera System

100000.00 INR/Unit

Product Details:

- Usage Pipe inspection, Drain and sewer inspection, Duct Inspection.

- Function Video recording, Picture capture, zoom, view content.

- Accuracy 100% %

- Click to View more

X

Pipe Inspection Camera System Price And Quantity

- 100000.00 INR/Unit

- 1 Unit

Pipe Inspection Camera System Product Specifications

- Pipe inspection, Drain and sewer inspection, Duct Inspection.

- Video recording, Picture capture, zoom, view content.

- 100% %

Pipe Inspection Camera System Trade Information

- 100 Unit Per Month

- 3 Week

Product Description

A pipe inspection camera system is a specialized tool used for inspecting the interior of pipes and conduits. It consists of a camera mounted on a flexible cable or a rigid rod, along with a display unit for real-time monitoring and recording. This technology is widely employed in various industries, including plumbing, construction, civil engineering, and maintenance, for inspecting the condition of pipelines, sewer lines, drainage systems, and other confined spaces.

Key components of a typical pipe inspection camera system include:

1. Camera Head:

- The camera head is the critical component responsible for capturing high-quality images or videos of the inside of pipes.

- It may have built-in LED lights to illuminate the pipe and improve visibility in dark environments.

2. Cable or Rod:

- The camera is attached to a flexible cable or a rigid rod, allowing it to navigate through pipes and bends.

- The length and flexibility of the cable or rod depend on the application and the type of pipes being inspected.

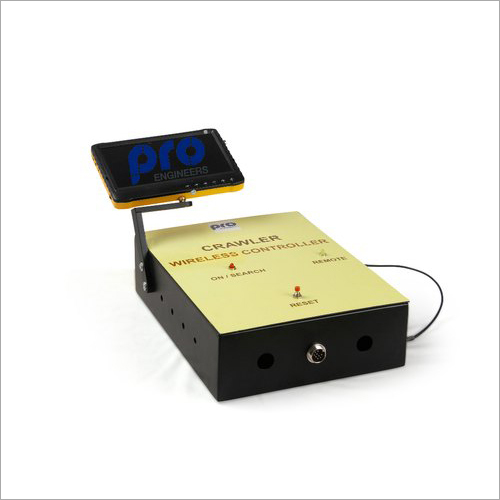

3. Monitor/Display Unit:

- The monitor or display unit provides real-time visual feedback from the camera.

- It allows operators to assess the condition of pipes, identify blockages, leaks, or other issues.

4. Control Unit:

- Some systems include a control unit that allows operators to manipulate the cameras movement, adjust lighting, and control other features.

5. Recording and Documentation:

- Many pipe inspection camera systems have the capability to record images or videos for documentation and analysis.

- Some systems may have built-in storage or the option to connect to external storage devices.

6. Power Source:

- Depending on the design, the camera system may be powered by batteries or an external power source.

Pipe Inspection Camera System Specifications:

1. Camera Size: 17mm

2. Battery Type: 6000mAh

3. Camera Resolution: 720 X 576 mm

4. Display Size: 40 x 240 x 86.5mm

5. Frequency: 50 to 60 Hz

6. Power Source: Battery

7. Power Supply: DC 12V

Applications of Pipe Inspection Camera Systems:

1. Plumbing and Sewer Inspection: Locating blockages, leaks, and other issues in sewer lines and plumbing systems.

2. Infrastructure Inspection: Assessing the condition of pipelines, tunnels, and other underground infrastructure.

3. Construction and Engineering: Inspecting newly installed pipes for quality control and ensuring proper installation.

4. Maintenance and Repair: Identifying damage or wear in pipes for proactive maintenance and repairs.

5. Environmental Monitoring: Assessing the condition of pipes in environmentally sensitive areas, such as water treatment plants.

Pipe Inspection Camera System Applications:

1. Plumbing and Sewer Systems:

- Locating blockages, cracks, or leaks in residential and commercial plumbing systems.

- Inspecting sewer lines for damage or obstructions without the need for extensive excavation.

2. Municipal Infrastructure:

- Assessing the condition of underground pipelines, stormwater drains, and sewer systems.

- Identifying structural issues, corrosion, or blockages in municipal water and wastewater networks.

3. Construction Industry:

- Inspecting newly installed pipes to ensure proper installation and detect any construction-related issues.

- Checking the integrity of pipelines in construction projects to prevent future problems.

4. Oil and Gas Industry:

- Inspecting pipelines for corrosion, damage, or potential leaks in oil and gas facilities.

- Assessing the condition of pipelines in refineries and petrochemical plants.

5. Power Generation Plants:

- Inspecting pipes and conduits in power plants, including nuclear, thermal, and renewable energy facilities.

- Identifying issues such as corrosion or erosion that may affect the efficiency and safety of the plant.

6. Manufacturing and Industrial Facilities:

- Inspecting process pipelines for any defects or abnormalities in manufacturing plants.

- Assessing the condition of pipes in industrial facilities to ensure compliance with safety and environmental standards.

7. Environmental Monitoring:

- Inspecting pipes in wastewater treatment plants to ensure proper functioning and compliance with environmental regulations.

- Monitoring underground pipes in environmentally sensitive areas to prevent contamination.

8. HVAC Systems:

- Inspecting heating, ventilation, and air conditioning (HVAC) ducts for blockages, damage, or contamination.

- Ensuring the cleanliness and efficiency of ventilation systems in residential and commercial buildings.

9. Shipbuilding and Marine Industry:

- Inspecting pipes in ship systems to ensure seaworthiness and prevent corrosion.

- Checking the condition of underwater pipelines and structures in ports and harbors.

10. Aerospace Industry:

- Inspecting pipes and conduits in aircraft to ensure structural integrity and safety.

- Checking fuel and hydraulic systems for any issues that may impact aircraft performance.

11. Telecommunications:

- Inspecting conduits and pipelines used for fiber optic cables or other communication infrastructure.

- Identifying any damage or blockages that may affect the transmission of signals.

12. Residential and Commercial Building Inspections:

- Inspecting plumbing systems in buildings for potential issues during pre-purchase inspections.

- Assessing the condition of drain and sewer lines in residential and commercial properties.

Pipe Inspection Camera System FAQ:

Q. What is a pipe inspection camera system?

Ans: A pipe inspection camera system is a specialized tool used to visually inspect the interiors of pipes, conduits, and other confined spaces. It typically consists of a camera mounted on a cable or rod, a display unit for real-time monitoring, and features for recording and documentation.

Q. How does a pipe inspection camera work?

Ans: The camera is attached to a flexible cable or rigid rod, which is inserted into the pipe. The camera captures images or videos of the interior, and these visuals are transmitted to a display unit in real time. Operators use the system to inspect the condition of pipes, identify blockages, leaks, or other issues.

Q. What are the key components of a pipe inspection camera system?

Ans: Key components include the camera head, cable or rod, monitor/display unit, control unit (optional), and features for recording and documentation. The camera head may have built-in LED lights for illumination.

Q. What types of pipes can be inspected with these systems?

Ans: Pipe inspection camera systems are versatile and can be used to inspect a variety of pipes, including sewer lines, plumbing pipes, industrial pipelines, stormwater drains, HVAC ducts, and more.

Q. What are the applications of pipe inspection camera systems?

Ans: Applications include plumbing and sewer inspection, municipal infrastructure assessment, construction site inspections, oil and gas pipeline inspection, power generation plants, manufacturing facilities, environmental monitoring, HVAC systems, shipbuilding, aerospace, and telecommunications.

Q. Can the camera system inspect pipes with bends and turns?

Ans: Yes, many systems are designed to navigate through pipes with bends and turns. The flexibility of the cable or rod allows the camera to move through the pipe and provide a comprehensive inspection.

Q. Is it possible to record the inspection for documentation purposes?

Ans: Yes, most pipe inspection camera systems come equipped with features for recording images or videos. This documentation is valuable for analysis, reporting, and future reference.

Q. What are the power sources for these camera systems?

Ans: The power source can vary. Some systems are battery-powered, providing portability, while others may require an external power source. The choice depends on the specific design and application requirements.

Q. Can these cameras be used in hazardous environments?

Ans: Some pipe inspection camera systems are designed for use in hazardous environments, such as those found in the oil and gas industry. These systems may be intrinsically safe and built to withstand challenging conditions.

Q. How do I choose the right pipe inspection camera system for my needs?

Ans: Consider factors such as the type and size of pipes you need to inspect, the length and flexibility of the camera system, the required image/video quality, and any specific features needed for your application. Consulting with a supplier or manufacturer can help you find the most suitable system.

Q. What maintenance is required for a pipe inspection camera system?

Ans: Regular maintenance may include cleaning the camera head, checking and replacing cables or rods if damaged, ensuring proper functioning of LED lights, and keeping the systems components in good condition. Follow the manufacturers guidelines for maintenance.

FAQs of Pipe Inspection Camera System:

Q: What is the accuracy of the Pipe Inspection Camera System?

A: The accuracy of the system is 100% for video recording, picture capture, zoom, and view content.Q: What are the main functions of the Pipe Inspection Camera System?

A: The main functions include video recording, picture capture, zoom, and viewing content.Q: What are the common uses of the Pipe Inspection Camera System?

A: The system is commonly used for pipe inspection, drain and sewer inspection, and duct inspection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free