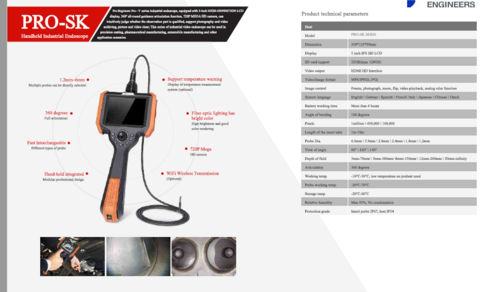

Borescope Video Scope

195000.00 INR/Unit

Product Details:

- Color Gray * Orange

- Application inspection system

- Material tungsten birded cable

- Product Type Borescope Video Scope

- Power battery

- Power Supply Battery

- Voltage 12 Volt (v)

- Click to View more

X

Borescope Video Scope Price And Quantity

- 1 Unit

- 195000.00 INR/Unit

Borescope Video Scope Product Specifications

- inspection system

- Gray * Orange

- 12 Volt (v)

- Battery

- battery

- Borescope Video Scope

- tungsten birded cable

Borescope Video Scope Trade Information

- Others

- 1000 Unit Per Day

- 10 Days

- All India

Product Description

A borescope, also known as a videoscope or inspection camera, is a tool used for visual inspection of hard-to-reach or inaccessible areas. It typically consists of a long, flexible tube with a tiny camera at the end, which can transmit images or videos to a display unit. Borescopes are commonly used in various industries such as automotive, aviation, plumbing, manufacturing, and construction for tasks like inspecting engines, pipes, ducts, turbines, and other machinery.

The main components of a borescope system include:

1. Probe: The flexible or rigid tube that contains the camera and lighting system. Probes come in various lengths and diameters to suit different applications.

2. Camera: The camera captures images or videos of the inspection area. It may have features such as adjustable focus, zoom, and articulation to navigate tight spaces.

3. Lighting: Built-in LED lights illuminate the inspection area, ensuring clear visibility in dark or poorly lit environments.

4. Display unit: A monitor or screen where the images or videos captured by the camera are displayed in real-time. Some borescopes may have wireless connectivity to display images on smartphones or tablets.

5. Control unit: Some advanced borescopes come with control units that allow users to adjust camera settings, capture images or videos, and save data for analysis or documentation.

Borescopes are valuable tools for detecting defects, damage, or blockages without the need for disassembly or invasive inspection procedures. They help improve efficiency, reduce downtime, and ensure safety in various industrial applications.

Borescope Video Scope Specifications:

1. 3.9 to 6mm camera

2. Up to 10 meter probe

3. 1280*960 resolution

FAQs of Borescope Video Scope:

Q: What is the application of the Borescope Video Scope?

A: The application of the Borescope Video Scope is for inspection systems.Q: What material is the cable made of?

A: The cable is made of tungsten birded cable.Q: What is the power source for the Borescope Video Scope?

A: The power source for the Borescope Video Scope is a battery.Q: What is the voltage requirement for the Borescope Video Scope?

A: The voltage requirement for the Borescope Video Scope is 12 Volt (v).Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese